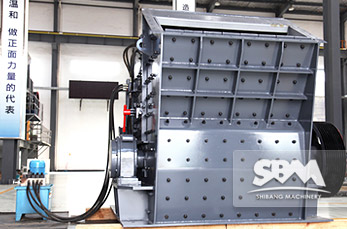

PFW Impact Crusher

- 0086-21-58386189, 58386176

- [email protected]

- 0086-21-58386211

- unique design top process:

This machine adopts the world-class manufacturing processes and select the most high-end material. The design of heavy rotor and strict detection means ensure the rotor of high quality. At the same time, the unique design of plate hammer fixed device makes the reliability of the board hammer higher.

- Semi-automatic operation simple and quick repair:

Hydraulic control system can quickly adjust outlet size and grain size. Automatic hydraulic open device can quickly complete the replacement of wearing parts, such as the plate hammer and reduce downtime and maintenance time.

- Steel structure and high bearing capacity:

This series crusher bearing seat with integral cast steel structure can ensure the stability of machine. Large size bearing can ensure higher bearing capacity.

- Simplify the process and widely used:

The two crushing chamber, in the coarse crushing operations, can simplify the process of crushing three chamber, in fine and super fine operation, has excellent performance. Two kinds of cavity can meet the requirements of the majority coarse crushing, fine operation.

Impact Crusher Advantages

| Model | Rotor Φ×L (mm) | Feed Opening (mm) | Max Feeding (mm) | Capacity (t/h) | Power (kw) | Motor Model | Machine Size (mm) |

| PFW1214II | Ф1150×1400 | 1100×1430 | 500 | 130-200 | 4-132 | Y315M-4/132 | 2400×2310×2550 |

| PFW1315II | Ф1300×1500 | 1200×1530 | 600 | 180-320 | 4-160 | Y315L1-4/160 | 2700×2570×2800 |

| PFW1318II | Ф1300×1800 | 1200×1830 | 700 | 240-400 | 4-200 | Y315L2-4/200 | 2700×2870×2800 |

| PFW1415II | Ф1400×1500 | 1450×1530 | 800 | 240-450 | 4-200 | Y315L2-4/200 | 3000×2700×3070 |

Feedstock Size: 250-700mm

throughout:70-400T/h

Field Of Application:the metallurgical, mining, cement, chemical, refractories, ceramics and other industrial sectors, as well as the highway construction, water conservancy, building stone, sand processing and other fields.

Suitable Material: all kinds of soft, hard ore for crushing, grinding operations, such as: limestone, calcite, feldspar, talc, barite, rare earth, clay, kaolin, gypsum, graphite etc.

Impact Crusher Working Principle

This machine is broken machinery, which use impact energy to crush material. When the material is sent into the plate hammer function area, it is broken under the high-speed impact of the plate hammer, and then is thrown into the impact device above the rotor to the second broken, and then is back to plate hammer working area to break from the counterattack lining. This process is repeated until the materials are crushed to the required size and discharged from the lower part of the machine. Adjusting the clearance between the impact frame and the rotor frame can change the size and shapeof materials. The machine adopts the spring safety device behind the counterattack plate. when the non-crushing matter enter crushing chamber, the two back frame will back, non-crushing matter will be discharged from the machine.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

PDF Download

PE Jaw Crusher

PE Jaw Crusher PEW Jaw Crusher

PEW Jaw Crusher PF Impact Crusher

PF Impact Crusher PFW Impact Crusher

PFW Impact Crusher CS Cone Crusher

CS Cone Crusher HPC Cone Crusher

HPC Cone Crusher PY Cone Crusher

PY Cone Crusher HCS Cone Crusher

HCS Cone Crusher VSI Shaft Impact Crusher

VSI Shaft Impact Crusher VSI5X Crusher

VSI5X Crusher Hammer Crusher

Hammer Crusher