- 0086-21-58386189, 58386176

- [email protected]

- 0086-21-58386211

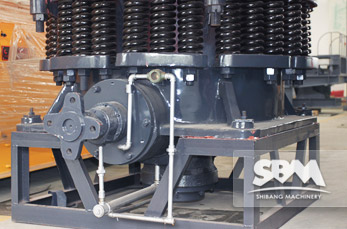

- Special sealing and reliable operation:

PY series cone crusher adopts two ways of sealing: dry oil or water so that the dust impurities cannot enter the machine body so as to ensure the smooth oil clean to prolong service life of the thrust ball bearing, sliding bearing. All this makes the machine run reliably.

- High production efficiency and ideal product:

The moving cone rotation, crushing process of materials and unloading process are alternating continuous along the work surface. It has high productivity. Between movable cone and static cone, there are dynamic parallel belts to make the product granularity uniformity; the cube-type product has a high proportion in the final product.

- Lower energy consumption and less wear:

Because the material is sandwiched between two cones,it is more easy to be crushed by extrusion, bending and shearing. The power consumption is low.Product size is uniform. The abrasion of dynamic cone working surface is even and loss is also lower.

- Overload protection and repair conveniently:

Spring safety system is overload protection device, which can allow the metal enter the crushing chamber without damage to the machine. At the same time, the machine is convenient to disassemble and convenient repair, greatly reducing the shutdown repair time.

Cone Crusher Advantages

| Model | Diameter of Bottom End of Conical Crushing Head(mm) | max feeding size | adjustment range of discharge opening | capacity(t/h) | power | Rev. of Eccentric shaft | Overall dimension(mm) |

| PYB600 | 600 | 75 | 12-25 | 40 | 30 | 356 | 2234×1370×1675 |

| PYZ600 | 600 | 35 | 3-13 | 5-23 | 30 | 356 | 2234×137×1675 |

| PYB900 | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 2692×164×2350 |

| PYZ900 | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 2692×164×2350 |

| PYD900 | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 2692×164×2350 |

| PYB1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 2790×1878×2844 |

| PYZ1200 | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 2790×1878×2844 |

| PYD1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 2790×1878×2844 |

| PYB1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 3910×2894×3809 |

| PYZ1750 | 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 3910×2894×3809 |

| PYD1750 | 1750 | 85 | 5-13 | 75-230 | 160 | 245 | 3910×2894×3809 |

| PYB2200 | 2200 | 300 | 30-60 | 490-750 | 260-280 | 220 | 4622×3302×4470 |

| PYZ2200 | 2200 | 230 | 10-30 | 200-580 | 260-280 | 220 | 4622×3302×4470 |

| PYD2200 | 2200 | 100 | 5-15 | 120-340 | 260-280 | 220 | 4622×3302×4470 |

Feedstock Size: 75-100mm

Throughout: 40-340t/h

Fields Of Application: Metallurgical industry, construction industry, chemical industry and phosphate industry etc.

Suitable Materials:Hard and medium hard ore, rock, such as iron ore, copper ore, limestone, quartz, granite, diabase, basalt.

Cone Crusher Working Principle

When spring crusher is at work, motor drives the eccentric shaft rotation through a horizontal axis and a pair of bevel gear. Crushing cone axis is forced to do dynamic swing movement by the eccentric sleeve. The broken wall surface come to or departs from rolling mortar wall now and then so that the ore in the crushing cavity is crushed continuously by extrusion and bending broken.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

PDF Download

PE Jaw Crusher

PE Jaw Crusher PEW Jaw Crusher

PEW Jaw Crusher PF Impact Crusher

PF Impact Crusher PFW Impact Crusher

PFW Impact Crusher CS Cone Crusher

CS Cone Crusher HPC Cone Crusher

HPC Cone Crusher PY Cone Crusher

PY Cone Crusher HCS Cone Crusher

HCS Cone Crusher VSI Shaft Impact Crusher

VSI Shaft Impact Crusher VSI5X Crusher

VSI5X Crusher Hammer Crusher

Hammer Crusher