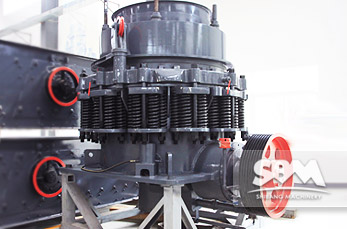

CS Cone Crusher

- 0086-21-58386189, 58386176

- [email protected]

- 0086-21-58386211

- High reliability and good stability:

With large diameter spindle, heavy main frame and the automatic control system of independent thin oil lubrication system , it can ensure the durable, reliable operation. Hard protection device can ensure that when the miscellaneous iron is through the crushing chamber, it can be able to quickly restore the original port of discharge and ensure the discharge size.

- Repair conveniently easy to operate:

All the parts are capable of dismounting from the upper or side and fixed cone and movable cone assembly can be conveniently disassembly. bronze sliding bearing can maintain excellent load-carrying properties in high shock and vibration environments. and it is more economic and more convenient repair than rolling bearing.

- Low cost and wide range of application:

Because of large capacity, high reliability and convenient repair, it greatly reduces the production cost. The machine makes cone spring crusher achieves the greatest performance to adapt to various crushing process: from coarse to fine and from fixed to mobile crusher station.

- Laminating crushing and ideal powder type:

This machine adopts laminated crushing principle, forming material protective layer so that it not only effectively reduces abrasion, prolong the service life of vulnerable parts, also can make the proportion of cube-type products in all improved obviously, and reduce flakiness gravel size.

Cone Crusher Advantages

| Model | Movable Cone Diametermm (inch) | Chamber Style | Opening Side | Closed Side | Discharging Opening (mm) | REV (r/min) | Power (kw) | Motor Model | Capacity (t/h) | Machine Size (mm) |

| Max.Feeding (mm) | ||||||||||

| CSB75 | 900 (3′) | medium | 83 | 102 | 9-22 | 580 | 6-75 | Y315S-6/75 | 45-91 | 2821×1880 ×2164 |

| coarse | 159 | 175 | 13-38 | 59-163 | ||||||

| CSD75 | 914 (3′) | fine | 13 | 41 | 3-13 | 580 | 6-75 | Y315S-6/75 | 27-90 | 2821×1880 ×2410 |

| medium | 33 | 60 | 3-16 | 27-100 | ||||||

| coarse | 51 | 76 | 6-19 | 65-140 | ||||||

| CSB160 | 1295 (4 1/4′) | fine | 109 | 137 | 13-31 | 485 | 6-185 | Y355M2-6/185 | 109-181 | 2800×2342 ×2668 |

| medium | 188 | 210 | 16-31 | 132-253 | ||||||

| coarse | 216 | 241 | 19-51 | 172-349 | ||||||

| CSD160 | 1295 (4 1/4′) | fine | 29 | 64 | 3-16 | 485 | 6-160 | Y355M1-6/160 | 36-163 | 2800×2342 ×2668 |

| medium | 54 | 89 | 6-16 | 82-163 | ||||||

| coarse | 70 | 105 | 10-25 | 109-227 | ||||||

| CSB240 | 1650 (5 1/2′) | fine | 188 | 209 | 16-38 | 485 | 6-240 | 181-327 | 3911×2870 ×3771 | |

| medium | 213 | 241 | 22-51 | 258-417 | ||||||

| coarse | 241 | 268 | 25-64 | 299-635 | ||||||

| CSD240 | 1650 (5 1/2′) | fine | 35 | 70 | 5-13 | 485 | 6-240 | 90-209 | 3917×2870 ×3771 | |

| medium | 54 | 89 | 6-19 | 136-281 | ||||||

| coarse | 98 | 133 | 10-25 | 190-336 | ||||||

| CSB400 | 2134 (7′) | fine | 253 | 278 | 19-38 | 435 | 6-400 | 381-726 | 5200×4300 ×4700 | |

| medium | 303 | 334 | 25-51 | 608-998 | ||||||

| coarse | 334 | 369 | 31-64 | 870-1400 | ||||||

| CSD400 | 2134 (7′) | fine | 51 | 105 | 5-16 | 435 | 6-400 | 190-408 | 5200×4300 ×4700 | |

| medium | 95 | 133 | 10-19 | 354-508 | ||||||

| coarse | 127 | 178 | 13-25 | 454-599 | ||||||

Feedstock Size: 13-369mm

Throughout : 27-1270t/h

Fields Of Application: It is widely used in mining ore crushing, high hardness of rock crushing, building material crushing, cement factory, quarry, concrete mixing station, dry mortar, power plant desulfurization, quartz sand etc.

Suitable Material:Granite, diabase, basalt, shale, quartz stone, pebble, limestone, iron ore, coal, nonferrous metal ore, cobble etc.

Cone Crusher Working Principle

When CS series spring cone crusher is at working, the belt, a big belt wheel, transmission shaft, bevel gear and bevel gear drive the eccentric sleeve to rotate under the force of motor. the crushing cone axis is forced to rotating swing under the eccentric sleeve to make the broken wall surface close to or depart from rolling mortar wall so that the materials are repeatedly subjected to impact, extrusion and bending and crushing in the fixed cone and movable cone crushing cavity. After repeated extrusion, impact and bending, materials are crushed to the required size, and discharged from the lower.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

PDF Download

PE Jaw Crusher

PE Jaw Crusher PEW Jaw Crusher

PEW Jaw Crusher PF Impact Crusher

PF Impact Crusher PFW Impact Crusher

PFW Impact Crusher CS Cone Crusher

CS Cone Crusher HPC Cone Crusher

HPC Cone Crusher PY Cone Crusher

PY Cone Crusher HCS Cone Crusher

HCS Cone Crusher VSI Shaft Impact Crusher

VSI Shaft Impact Crusher VSI5X Crusher

VSI5X Crusher Hammer Crusher

Hammer Crusher