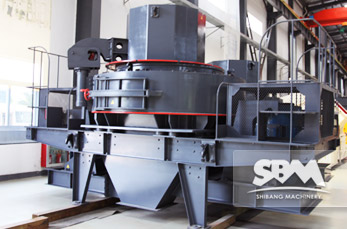

VSI Shaft Impact Crusher

- 0086-21-58386189, 58386176

- [email protected]

- 0086-21-58386211

- Processing a large quantity of uniform size:

The maximum throughput of up to 520 tons / hour, compared with the traditional equipment and under the same power, the yield increased by 30% and stable. The product of a cube, grain shape, reasonable distribution, fineness modulus can be adjusted, especially suitable for artificial system sand and stone plastic.

- The vulnerability of low energy consumption and long service life:

The optimal design of crushing cavity impact angle, friction material and wear resistant parts, directly reduces the equipment costs; with the German original thin oil lubrication station, completely solve the problem of the spindle bearings, bearing temperature is constant, the maintenance cycle and service life extension.

- Easy operation, convenient maintenance:

Light weight of equipment, installation is diversiform, convenient operation, once the specific use, only need to tweak, can maximize its excellent performance; equipped with hydraulic cover opening device, the crushing cavity parts repair replacement is convenient, save time and effort.

- Advanced technology of energy saving and environmental protection:

The core components are selected well-known international brands (using high precision class TIMKEN brand), to ensure that the system low failure rate; equipment, low working noise, unique air circulation system, greatly reduced the efflux air, dust, environmental protection.

Shaft Impact Crusher Advantages:

| Model | Feed at center&sides | Feed at center | Soft Material | Hard Material | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| Capacity (t/h) | Max.Feeding (mm) | |||||||

| VSI7611 | 120-180 | 60-90 | 35 | 30 | 1700-1890 | 4-55×2 | Y250M-4/55 | 4100×2250×2258 |

| VSI8518 | 200-260 | 100-130 | 40 | 35 | 1520-1690 | 4-90×2 | Y280M-4/90 | 4140×2280×2425 |

| VSI9526 | 300-380 | 150-190 | 45 | 40 | 1360-1510 | 4-132×2 | Y315M-4/132 | 4560×2450×2780 |

| VSI1140 | 450-520 | 225-260 | 50 | 45 | 1180-1310 | 4-200×2 | Y315L2-4/200 | 5100×2690×3200 |

Feedstock Size: 30-50mm

Throughout: 60-520T/h

Fields Of Application:It is applied in sand quarry, mixing station, dry mortar, quartz sand, construction waste crushing industries, station to provide quality sand aggregate for highway, railway, construction, municipal, hydroelectric dam construction and concrete mixing.

Suitable Materials:River gravel, limestone, quartz stone, cobblestone, coal gangue, basalt, granite, diabase, etc.

Shaft Impact Crusher Working Principle:

VSI sand making machine using selective fragmentation and cleavage of advanced crushing principle, applied directly to the material enough kinetic energy, and the kinetic energy is converted to overcome the broken materials required by the impact. The material basic along its natural texture surface, cleavage fracture, grain shape, its consumption is low. Convert the machine can implement "stone dozen stone" and "hot stone" two principles.

Center into hopper: material feeding into, the center feeding hole into the high-speed rotation of the left wheel, was rapidly accelerated in the left wheel, the acceleration of up to tens of times the acceleration of gravity, then high speed from the left wheel injective, first of all to another part of the material and the rebound after free falling impact, and the impact to the material. Liner (stone dozen stone) or counter block (hot stone), bounce oblique impact to the top of the vortex chamber, and changes its direction of motion, deflection downward movement, and is emitted from the impeller material impact of a continuous curtain material. In this way, a piece of material by crushing cavity two times to many times the chance of hitting, friction and grinding effect on eddy current. The crushed material is discharged.

Center feeding with annular waterfalls fall into hopper: material feeding into, in the annular aperture falls, is divided into two shares of plate material, a unit distributing disc into the high-speed rotation of the left wheel, another from the tray drop round. Enter the left wheel material, was rapidly accelerated in the left wheel, the acceleration of up to tens of times the acceleration of gravity, then high speed from the left wheel injective, first from another part of the material distributor around free falling impact crushing, and impact to the eddy cavity eddy lining layer, is material lining layer rebound, oblique to blow to the top of the vortex chamber, and changes its direction of motion, deflection downward movement, and from the impeller from the impact of materials to form a continuous material curtain. In this way, a material in the vortex crushing cavity received two times to many times the chance of hitting, friction and grinding effect. The crushed material is discharged.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

PDF Download

PE Jaw Crusher

PE Jaw Crusher PEW Jaw Crusher

PEW Jaw Crusher PF Impact Crusher

PF Impact Crusher PFW Impact Crusher

PFW Impact Crusher CS Cone Crusher

CS Cone Crusher HPC Cone Crusher

HPC Cone Crusher PY Cone Crusher

PY Cone Crusher HCS Cone Crusher

HCS Cone Crusher VSI Shaft Impact Crusher

VSI Shaft Impact Crusher VSI5X Crusher

VSI5X Crusher Hammer Crusher

Hammer Crusher